From H2O-Online

Download the whole article here

Biofouling is one of the most common types of pollution in reverse osmosis (RO) systems. The ultrapure water (UPW) plant in Emmen has successfully applied BODAC, a special technology using activated carbon filtration as RO pre-treatment since 2010.

Written by Marcel Boorsma (WLN), Simon Dost (WMD), Hilde Prummel (WLN)

NieuWater, a joint venture between the Drenthe Water Services provider and the Vechtstromen water board, has been producing ultrapure water (UPW) for NAM since 2010. The UPW plant can yield up to 8,200 m3 of ultrapure water per day, which NAM uses to produce steam. To produce this UPW, the plant processes the effluent of the Emmen WWTP.

This is the second of a series of three articles about the UPW plant at the Emmen WWTP. For the first article, please click here.

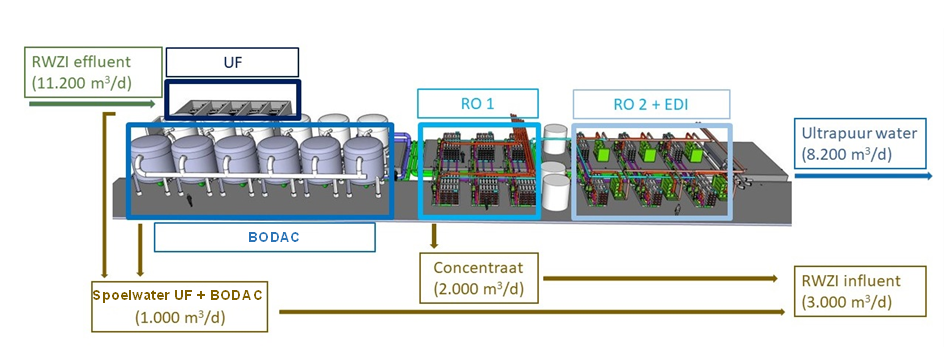

A key requirement for the design of the UPW plant was to keep the use of chemicals to a minimum. Because the quality of the WWTP effluent is highly variable, the treatment system had to be robust. Thanks to the extensive combination of various treatment techniques, the plant has shown itself to be well capable of coping with these changes in feed water quality. The pre-treatment step consists of ultrafiltration (UF), followed by a series of two BODAC (Biological Oxygen-Dosed Activated Carbon) Filters. Combined with a double-pass reverse osmosis (RO) system and, finally, an electro-deionisation (EDI) system, the plant upgrades the WWTP effluent to almost 100% pure water. All rinse water and concentrate streams are returned to the WWTP. Figure 1 shows a schematic diagram of this process.

Figure 1. Process flow diagram of the Emmen UPW plant

Function and

operation of BODAC filters

When using reverse osmosis as a desalination technique, it is essential that

the feed water is particle free and has a low pollution potential. Ultrafiltration

(UF) and BODAC filtration serve to remove suspended solids and nutrients (e.g.

ammonium), respectively, from the effluent of the WWTP. The UF permeate has the

potential to lead to problematic biofouling on the reverse osmosis membranes

[1].

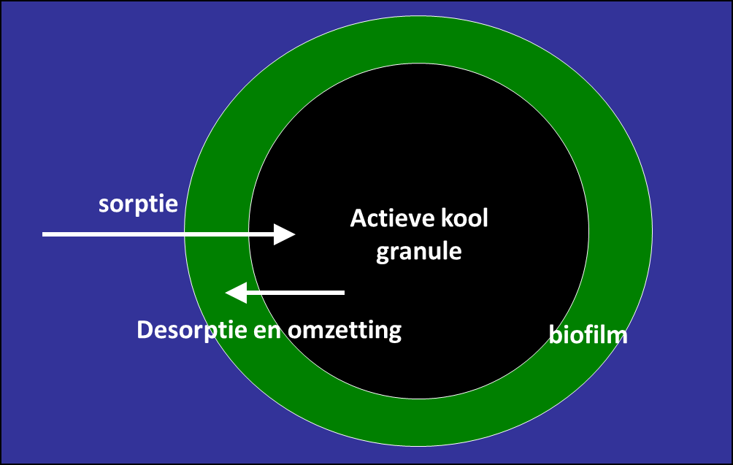

All over the world, the uncontrolled accumulation of biofouling on these membranes is combated with biocides. Because such biocides may be harmful to aquatic life, NieuWater opted for a more environmentally friendly alternative for its UPW plant, namely BODAC filtration. The underlying idea is that conversion processes and biological growth are allowed to take place in a controlled manner in a designated part of the treatment system. It is assumed that the role of activated carbon is twofold: (1) surface for biofilm formation and (2) sorption and desorption of substrate. As a result, not only are easily absorbable organic compounds converted by biomass, but the same biomass is also given the time to break down and convert more stubborn substances (see figure 2). Aerobic conditions are essential for this process, hence the dosing of oxygen.

Figure 1. Process flow diagram of the Emmen UPW plant

BODAC design:

position and dimensions

Based on the idea that bioreactors are fed with particle-free water, the choice

was made to place the BODAC filters after the ultrafiltration. The position of

BODAC in the treatment train and the dimensions of the filters are based on the

pilot study carried out prior to the design stage of the UPW plant, which took

place in 2006-2007 [1].

The first BODAC filter (the pre-filter) has been set to a filtration rate of approximately 10 metres per hour and has a retention time of 16 minutes. The second BODAC filter (the post-filter) has been set to a filtration rate of approximately 5 metres per hour and has a retention time of 32 minutes. Every three to six days, depending on biofilm production, the resistance in the filters reaches a point that they must be backwashed. Thanks to the continuous dosing of oxygen to both filters, the system remains aerobic.

The quality of the BODAC filtrate is checked online by means of oxygen tests and a particle monitor. Apart from containing as few nutrients as possible, the particle content of the RO feed water should also be as low as possible. If, for any reason, the particle level of the effluent is too high, e.g. immediately after the filters have been backwashed, the flow of BODAC filtrate to the RO membranes will be temporarily paused until the particle index has reached acceptable levels.

No biofouling

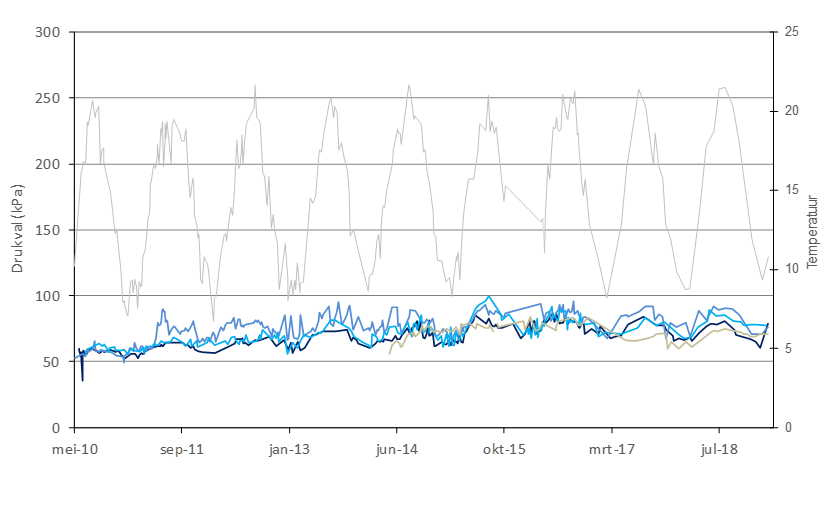

The BODAC system does exactly what it was designed to do nine years ago: there

is no observable biofouling on the downstream RO systems. The normalised

pressure drop across the membranes (figure 3) is stable and does not show the

rapid exponential increase typical of biofouling.

Figure 3. Pressure drop across the first RO stage over the period 2010 – 2019. The pressure drop has been normalised, i.e. corrected for temperature. Blue lines: pressure drop across the first stage of the various RO skids, grey line: temperature

The same situation, i.e. the absence of biofouling, can be seen at other locations in the treatment plant. The filtrate space below the BODAC filter is still clean after nine years and there is virtually no biofouling (see figure 4).

Figure 4. Filtration space under the BODAC filters: no biofouling

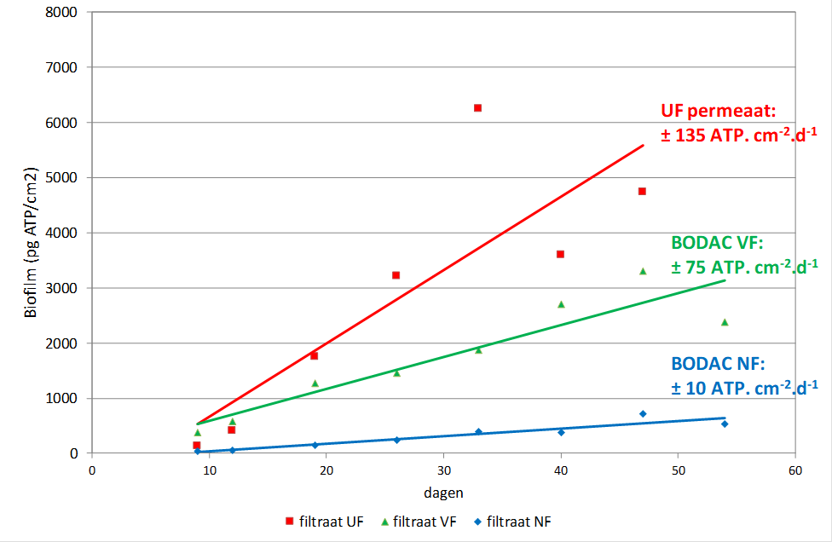

A measure of the biofouling potential of water is its so-called biofilm formation rate (BFR). This is a standardised method [2] that was originally developed for drinking water. Water flows along glass rings at a certain speed. The accumulation of Adenosine Triphosphate (ATP) on these rings is a measure of BFR. BODAC filtration reduces BFR from approximately 135 to 10 pg (picogram, 10-12 grammes) ATP/cm2.day (figure 5), marking a significant decrease in biofouling potential.

Figure 5. Biofilm formation rate on UF permeate and after BODAC filtration (PF=pre-filter, PF=post-filter)

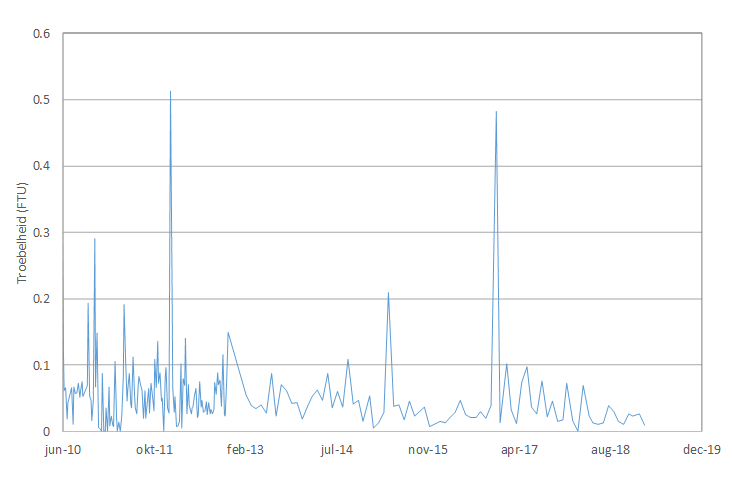

The greatest risk involved with the current position of the BODAC filters in the treatment setup (between ultrafiltration and RO) is particle leaching. The pilot study (2006-2007) showed that anaerobic conditions in BAC filtration processes lead to biomass/particle leaching. To prevent anaerobic conditions from occurring, oxygen is dosed to both filters. The total amount of oxygen dosed to the series averages 16 mg/l, of which approximately 55% is destined for the pre-filter and 45% for the post-filter. There is virtually always complete nitrification in the BODAC filters and 20% of the dissolved organic matter (DOC) in the water is broken down. The average turbidity of the BODAC effluent is low, averaging less than 0.1 FTU (Formazin Turbidity Unit, see figure 6).

Figure 6. Turbidity after BODAC filtration over the period 2010-2018

Sustainable, robust

pre-treatment

Looking back over the past nine years, it can be concluded that Biological

Oxygen-Dosed Active Carbon filtration has been an excellent RO pre-treatment

step. The implementation of a series of two BODAC filters has enabled the

treatment system to cope with the varying water quality of the WWTP effluent

and to always produce water with a high biological stability as feed water for

reverse osmosis. To date, no significant biofouling has been observed on

reverse osmosis membranes.

The investment costs for BODAC are relatively high compared to alternatives such as biocide dosing. In Emmen, these costs can be written off over an extended period of time thanks to the long-term contract with NAM. These relatively high investment costs are offset by savings in operating expenses. The replacement costs for the RO membranes, which have not yet been replaced since the system was put into service in 2020, and the use of chemicals (no flocculants, less cleaning agents and no biocides) are very low. This makes BODAC a sustainable and robust pre-treatment for RO systems, especially when the wastewater is reused.

No biofouling

The BODAC system does exactly what it was designed to do nine years ago: there

is no observable biofouling on the downstream RO systems. The normalised

pressure drop across the membranes (figure 3) is stable and does not show the

rapid exponential increase typical of biofouling.

REFERENCES

1. Maas, P. van der et al. (2010). ‘Beheersing vervuiling RO membranen door

biologische actiefkoolfiltratie’. H2O (18) 41 – 44.

2. Kooij, D. van der et al. (1997). ‘Bepaling en betekenis van de

biofilmvormende eigenschappen van drinkwater’. H2O (25) 767

– 771.