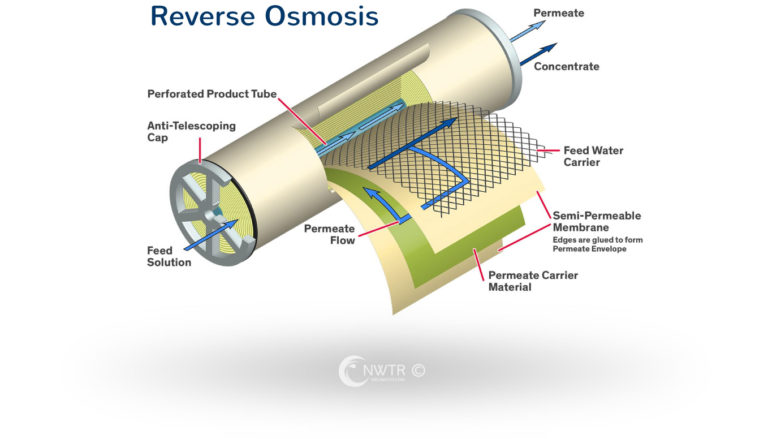

The first RO step manages to remove 98% of all dissolved salts (minerals). The pressure tubes are six metres long and the coiled membranes have a combined surface area of 40,000 m2, or approximately eight football pitches. The concentrate (approx. 20% vol.) is returned to the WWTP and the clean water continues to step 4.

No biofouling

Because the water has been depleted of all nutrients (step 2), no biofouling can accumulate on the membranes. As a result, there is no need for biocides. On top of that, the membranes only need to be cleaned sporadically. The plant in Nieuw-Amsterdam has been in operation for a decade now and the membranes are still not in need of replacement.

Minimal antiscalant

A second problem common in RO systems is clogging due to mineral deposits. A pressure sensor in the last RO stage detects deposits and automatically signals the system to add antiscalant. Thanks to this in-process measurement, developed by NWTR, much less antiscalant is needed than usual. At the same time, the timely, accurate dosing of antiscalant, linked to the quality of the influent, increases the operational reliability of the system.