From H2O-Online

Download the PDF here.

NieuWater has been producing ultrapure water from the effluent of the Emmen WTTP since 2010. Based on almost 10 years of experience, it can be concluded that WWTP effluent is an excellent source for industrial water.

Written by Gerrit Veenendaal (Nieuwater), Dick Kuiper (Vechtstromen Water Board), Simon Dost (WMD Drinking Water), Peter van der Maas (WLN / VHL University of applied sciences)

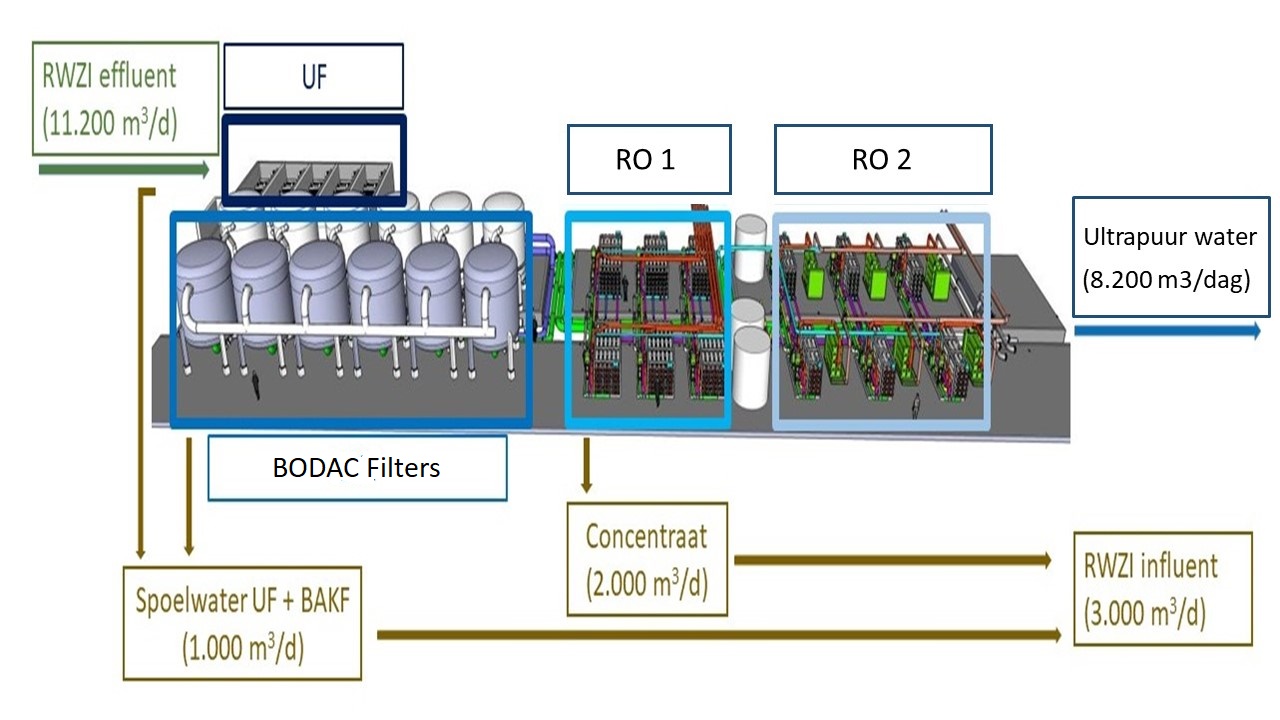

NieuWater, a joint venture between the Drenthe Water Services provider WMD and the Vechtstromen water board produces up to 8200 m3 of ultrapure water (UPW) a day for NAM in Schoonebeek [1]. NAM uses the UPW to produce steam, which is injected into the Schoonebeek oil field to heat up the oil in the subsoil and thus reduce its viscosity. NAM’s key criterium is that the water has an extremely low conductivity of < 0.2 µS/cm, so the most important function of the UPW plant is to remove salts and other substances from the water.

In south-east Drenthe, the availability of surface water and groundwater is limited in summer, prompting the decision to use effluent from the Emmen WWTP as a source for UPW production. The plant is located in an area that typically experiences shortages of water/surface water in summer. During this time, water is pumped from the IJsselmeer to the east of Drenthe. Partly for this reason, it was decided at the time to develop a minimally chemical treatment system, whilst also restricting waste streams as much as possible.

Based on membrane technology

To minimise the use of chemicals, the decision was made to treat water with membrane processes: ultrafiltration (UF) to remove particles and reverse osmosis (RO, in two steps) as the main treatment process to remove salts [2].

The WTTP effluent still contains relatively many nutrients, which can easily lead to the uncontrollable biofouling on RO membranes. The big question when designing the UPW plant was, therefore: is there a way to inhibit biofouling that does not involve chemicals (standard practice)? An alternative was found in a special type of biological activated carbon filtration known as BODAC, which involves dosing oxygen to maintain aerobic conditions in the bioreactors. The concentrate streams from the UF process and the first RO process and the rinse water from the BODAC filters are returned to the WTTP influent.

The second task involved post-treating and removing the last remnants of salt from the water. In the past, this was mainly done with ion exchangers, which have the disadvantage of using a relatively large amount of chemicals for regeneration and therefore produce a relatively large waste stream. Instead, the system features a new, sustainable alternative: electro-deionisation (DEI). This technique also involves ion exchange, but allows for continuous regeneration by means of ion-selective membranes and an electric field, whilst using a negligible amount of chemicals. When the UPW plant was put into service in 2010, its EDI system was the largest in the world. Figure 1 shows a schematic diagram of the full treatment system.

Figure 1. Diagram of treatment steps at the NieuWater UPW plant in Emmen

Biological Oxygen-Dosed Active Coal Filtration

In order to prevent biofouling of RO membranes in an environmentally friendly way, the decision was made to implement BODAC filtration as a pre-treatment process. The aim of pre-treating water before reverse osmosis is to completely eliminate all nutrients for bacteria, so that they cannot grow on the RO membranes. The idea was to use the activated carbon as an absorbent for nutrients and carrier material for bacteria. In the design period, in the years 2006 to 2008, biological activated carbon filtration was still a new pre-treatment method for RO, so there were no references to consider.

During the design period, the application of BODAC filtration as an innovative technology was tested as a pilot [3]. After showing promising results, the decision was made – in close consultation with NAM, as the client – to implement a BODAC pre-treatment stage for RO. The BODAC filters are fed with effluent that has been stripped of all particles by means of ultrafiltration (UF). Pure oxygen is then added to prevent anaerobic conditions from arising in the active carbon filters.

Innovative water

technology

The innovative application of BODAC filtration combined with membrane

technology has proven to be an excellent decision. In the nine years since the

UPW plant was put into service, no significant biofouling has occurred. Now,

almost a decade later, there is still no reason to replace the UF or RO

membranes. The higher investment costs of the BODAC concepts have largely been

recouped thanks to the longer lifespan of the membranes, as well as savings on

chemicals and maintenance. There was sufficient scope for the application of

innovative, sustainable technology and the corresponding investments because of

the relatively long-term contract with NAM (25 years).

In addition to preventing biofouling on membranes, BODAC technology appears to be highly suited to remove a high percentage of pharmaceuticals from WWTP effluent. These remarkable experiences with BODAC are described in separate articles.

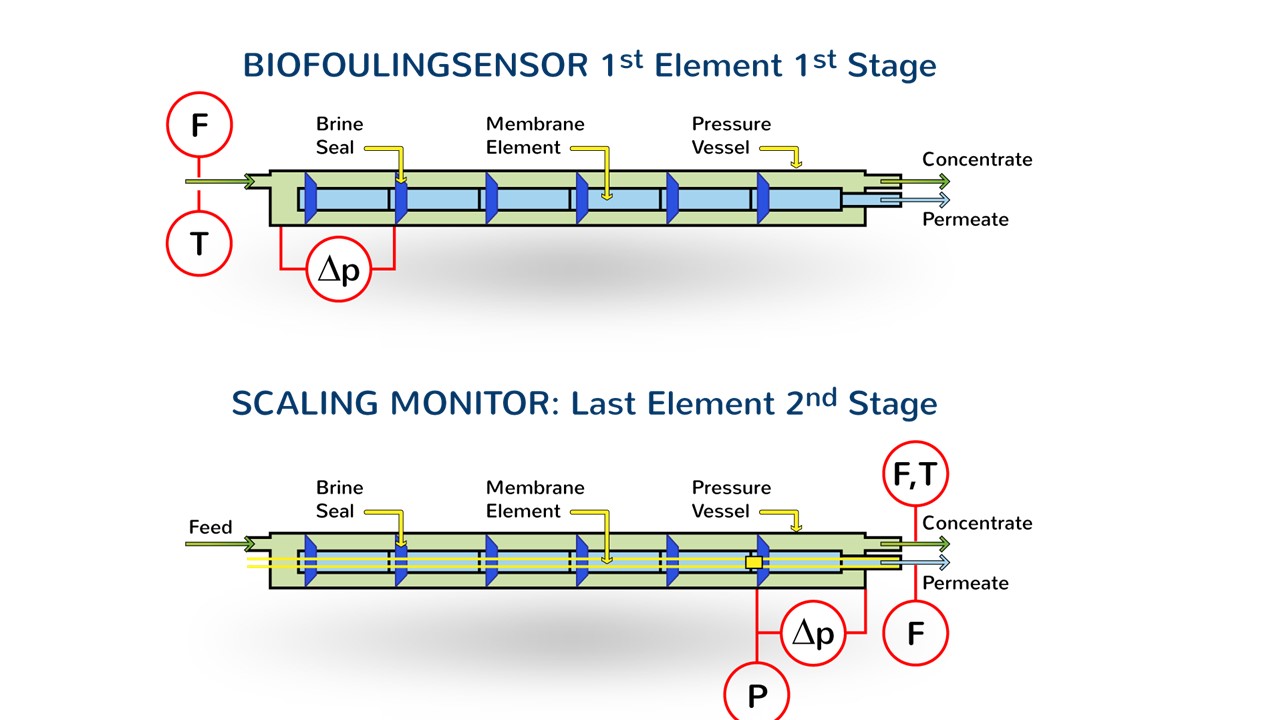

In addition to BODAC filtration, the UPW plant is also home to various other innovations, such as the use of special pressure sensors on RO membrane pressure tubes (figure 4). These sensors constantly measure the pressure drop after the initial membrane of the first stage and after the last membrane of the second stage as an indicator of scaling and biofouling, respectively. With these sensors, any membrane contamination can be detected at an early stage, so that the use of antiscalants can be kept to a minimum. A trial is currently underway with a dynamic antiscalant dosing system, based on the quality of the influent, which may further reduce the system’s dependence on chemicals.

Figure 4. Biofouling and scaling sensors

The innovative water technology in the UPW plant contributes to a robust water treatment system that can also cope with varying conditions. Naturally, there is more to it than just technology. An expert team that can operate and service the system is worth its weight in gold.

In conclusion

Our experiences in Emmen shows that WWTP effluent is, in principle, an excellent source to produce high-quality process water. The potential of this source will only increase if water boards introduce additional treatment steps to remove pharmaceuticals, for instance.

REFERENCES

1. Hoogsteen, K. and Wolthuis, W. (2010). ‘NieuWater opmaat voor betere samenwerking in de waterketen’. H2O (2010), 18, p. 6-7.

2. Bos, R. en Schuiling, R. (2010). ‘Ultrapuur water uit afvalwater’. H2O(2010), 18, p. 8-10.

3. Maas, P. van der, Majoor, E., Dost, S., Schippers, J. (2010). ‘Beheersing vervuiling RO-membranen met biologische actiefkoolfiltratie. H2O (2010), 18, p. 41-44.